TM 5-3655-210-12

refrigeration for the contents of both pressure vessels,

and to equalize the liquid levels and pressures.

2-7. Reduced Conversion Cycle

a. This operation can be performed only when

liquid carbon dioxide is present in the storage pressure

vessel. Perform the following steps when converting

solid carbon dioxide into the conversion pressure

vessel. The refrigeration controls should be set for

automatic operation as follows: Make certain the motor

starting switch and the reversing switch are in the OFF

position; and the power line is connected to the trailer

208 VAC power receptacle (1, fig. 2-11). Disengage

the three countershaft clutches (1, 2, and 3, fig. 2-3).

Turn the motor' starting switch (fig. 2-9) to the HAND

position. Turn the reversing switch to one of the ON

positions only long enough to observe the rotation of the

shaft. The shaft should rotate counterclockwise when

viewed from the shaft end of the motor. If the shaft

rotates in the proper direction, turn the motor starting

switch to the AUTOMATIC position, and return the

reversing switch to the same ON position. If the shaft

rotates in the wrong direction, turn the motor starting

switch to the alternate ON position. The position of the

reversing switch must not be changed unless a power

source of different phase sequence is used. With the

above steps performed, the electric motor will start

whenever the high tank pressures close the tank

pressure switch, which controls the electric motor. The

refrigeration clutch (3, fig. 2-3) engaged.

b. Position the valves as indicated in figure 2-17.

Refer to Table 2-1 for valve identification.

c. When the pressure in the conversion pressure

vessel is 0 psi, close valve 8. Open the manway on the

conversion pressure vessel and pack the vessel with

approximately 4,000 pounds (1800 kg) of solid carbon

dioxide. Reseal the manway as follows:

(1) Install the gasket (2, fig. 2-15) on the

cover (1).

(2) Position the cover in the vessel.

(3) Position the bolts (6), clamps (5),

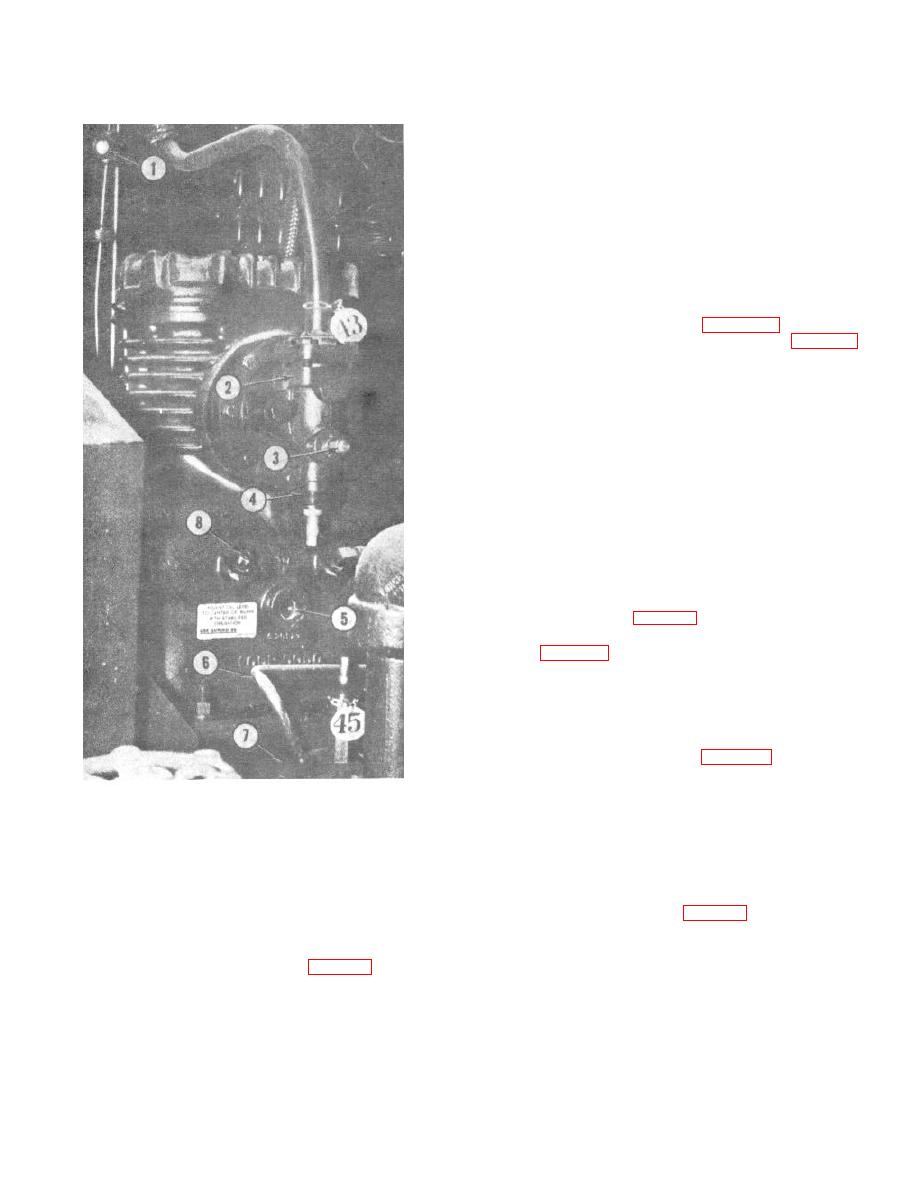

1.

Refrigerant sight glass

5.

Oil level sight glass

flatwashers (4), and secure with the nuts (3).

2.

Suction valve

6.

Receiver tank inlet line

(4) Replace the block of insulation (2, fig. 2-

3.

Freon charging port

7.

Receiver

14).

4.

Suction valve shut-off

8.

Oil filler plug

(5) Lower the hatch (1), and secure with locks

Figure 2-12. Refrigeration compressor, installed view.

(4).

d. Turn on the switch, (9, fig. 2-2), mounted on the

(5) Disengage the transfer pump clutch and

dc control panel, to start the conversion heater.

close valves 2 and 9.

e. To reduce the conversion cycle time, close

(6) Set the unit for automatic operation, and

valve 7 (fig. 2-17) and then open valves 8 and 9. Keep

engage only the refrigeration clutch (3, fig. 2-3).

the valves in this position until the conversion pressure

With all the liquid contained in the storage pressure

vessel pressure increases to 60 psi (4.218 kg per sq

vessel, the valves should be in the normal position as

cm), or the storage pressure vessel pressure reduces to

indicated in figure 2-13.

150 psi (10.545 kg per sq cm). When either of these

(7) If liquid was contained in the storage

pressure vessel during conversion, close valve 7 (fig. 2-

13) and then open valves 5, 8 and 9 to provide

2-13