TM 5-3655-210-12

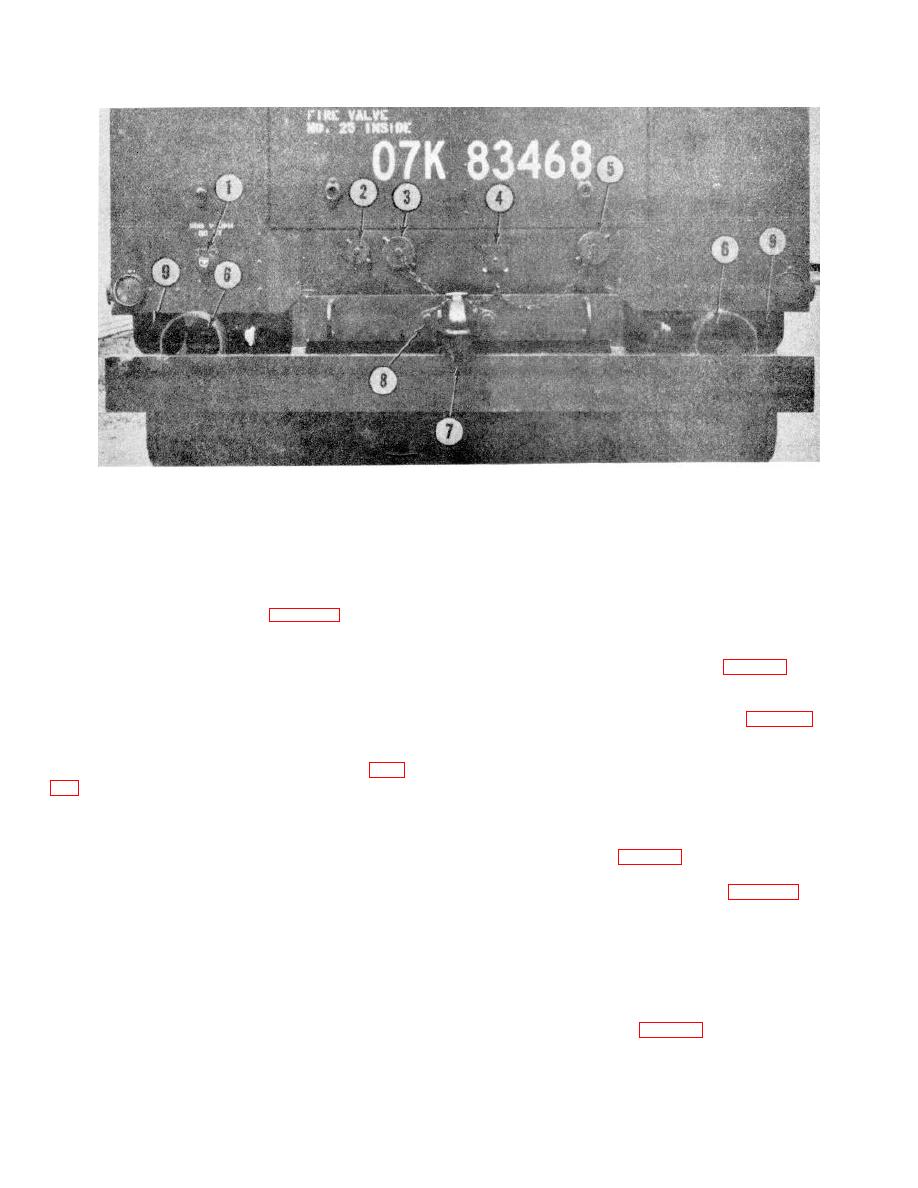

1. 208 v, ac power receptacle

4. 24 v, de receptacle

7. Pintle hook

2. Vapor equalizing line

5. Liquid fill line

8. Capscrew

3. Liquid fill line (pump by-pass)

6. Blackout stop and taillight

9. Stop and taillight, service

Figure 2-11 .

Power receptacles, installed view.

soap and water to the hatch seal. Bubbles will indicate

(1) Install the gasket (2, fig. 2-15) on the

a leak.

cover (1).

i. After conversion is completed, turn off the

(2) Position the cover in the vessel.

(3) Position the bolts (6), clamps (5),

conversion heater control switch (9, fig. 2-2) and if the

flatwashers (4), and secure with the nuts (3).

liquid is to be transferred to the storage pressure vessel,

(4) Replace the block of insulation (2, fig. 2-

transfer as follows: (1) Set the driving unit for manual

14).

operation by placing toggle switch (2, fig. 2-2) in the

(5) Lower the hatch (1), and secure with locks

trailer position. The circuit breaker (3), mounted on the

(4).

engine control panel should be ON or in the up position.

Prime the carburetor. Hold the gasoline engine START

switch (12) mounted on the engine control panel up,

until the engine starts, then release the switch. To stop

the conversion heater.

h. The conversion heater will cycle on and off

the engine hold the engine STOP switch (11) up until

the engine is completely stopped.

Disengage all

during the initial stages of conversion. This will occur

clutches (1, 2, and 3, fig. 2-3).

since the heater fluid circulating through the coil is not

(2) Set the valves as indicated in figure 2-16

sufficiently cooled by the carbon dioxide, and causes the

and start the driving unit. Refer to Table 2-1 for valve

heater thermostat switch to open and close. The heater

identification.

will continue to operate until the temperature of the

(3) Close valves 1, 3, 5 and 10 (fig. 2-16).

heating fluid, returning to the heater, reaches 73.9C.

Open valve 4. Open valves 2 and 10. When liquid

(165F.). The heater will remain off until the fluid

carbon dioxide appears at valve 10, close the valve and

temperature reduces to 65.6C. (150F.). The conversion

engage the clutch to the transfer pump.

cycle will continue until the pressure in the conversion

(4) Continue to operate the transfer pump until

pressure vessel reaches 275 psi (19.3325 kg per sq cm).

the conversion pressure vessel is empty, as indicated by

At this pressure, the tank pressure control switch will

the liquid level gage (2, fig. 2-4).

open the circuit, to stop the heater. During the use of

the conversion vessel the hatch cover should be

periodically leak tested by applying a solution of

2-12