TM 5-3655-210-12

regulating valve may remain constant until all cylinders

have been filled. This will reduce packing wear.

CAUTION

Do not allow the cylinder filling unit to idle at

charging pressure for long periods of time.

This will cause pressure build-up within the

pressure vessels and wear to the cylinder

filling unit.

j. After the cylinder filling operations are

complete, adjust valve 14 (fig. 2-25) counterclockwise

to reduce the gage pressure to approximately 300 psi

(21.18 kg per sq cm). Disengage the cylinder filling unit

clutch (2, fig. 2-3) and set the valves for the normal

position as indicated in Figure 2-13. Set the controls for

automatic operation, and engage the refrigeration clutch

(3) (fig. 2-3). Remove the cylinder filling hoses, and

replace in the storage compartment.

2-15. Determining Liquid Level While Pumping

a. Liquid Level Gage. The unit is equipped so that

the liquid level gages (2 and 4, fig. 2-4) indicate the

TS 024503

contents of the pressure vessels (in tenths of capacity)

even during pumping. Thus the contents can be

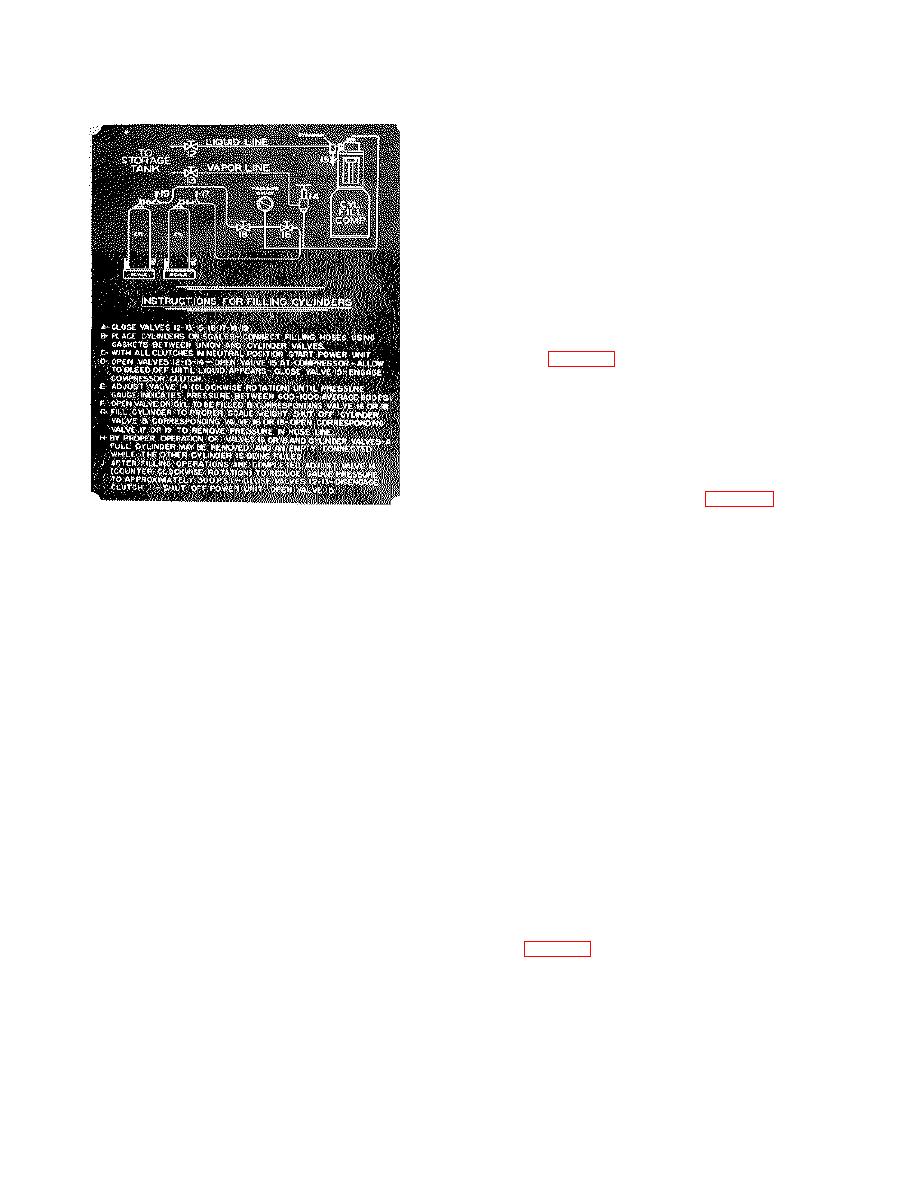

Figure 2-25.

Cylinder filling operation .

determined by reading the gages and allowing for slight

time lag.

b. Liquid in Vapor Equalizing Line. When filling

operator will determine a suitable charging pressure.

g. Open valve on cylinder to be filled and

the pressure vessels, it is usually desirable to fill them

corresponding valve 16 or 18 (fig. 2-25).

completely. The normal course of the carbon dioxide

NOTE

during filling is for liquid to enter at the bottom of the

As the empty cylinder starts filling, the

vessels while carbon dioxide vapor flows out at the top

charging pressure, indicated on the pressure

of the vessels, returning to the tank from which the

gage, will decrease and gradually regain the

liquid is being pumped. When the liquid level in the

charging pressure as the cylinder fills.

pressure vessel rises until it reaches the bottom of the

vapor equalizing dip tube inside the vessel, the tank is

h. Allow the cylinder to fill until the proper v/eight

at full capacity.

NOTE

is reached. When the cylinder is full, close the valve on

the cylinder and the corresponding valve 16 or 18.

If pumping is continued after capacity is

Bleed off pressure trapped in the hose through valve 17

reached, liquid carbon dioxide will enter

or 19. Do not overfill the cylinder. The total weight of a

the vapor equalizing line instead of

completely charged cylinder is stamped on the cylinder.

vaporous carbon dioxide. The cold liquid

in the vapor equalizing line will cause that

CAUTION

line to accumulate frost, and indicate that

If a cylinder is overfilled, discharge the

complete filling has been obtained.

excess carbon dioxide so that the

c. Pressure Gage. Another method of determining

frangible disc on the cylinder is not

ruptured.

when the tank is full is to observe the pressure gages (1

i. If cylinders of the same size are being filled

and 3, fig. 2-4). As long as liquid enters the bottom of

the vessel and vapor returns through the vapor

alternately, in pairs, with continuous charging taking

equalizing line, the pressure will remain approximately

place, one connection is used for filling and the other

constant. 'As soon as the liquid level reaches the vapor

connection is used for attaching or removing the second

equalizing dip tube and liquid is forced into the vapor

cylinder. Setting of the pressure

equalizing line, the pressure will suddenly begin to rise.

2-24