TM 9--2520--215--34

0047 00--10

OUTPUT REDUCTION GEAR OUTPUT SHAFT AND RELATED PARTS REPAIR

– CONTINUED

0047 00

ASSEMBLY – Continued

WARNING

Use gloves or tongs when handling hot bearings to prevent injury.

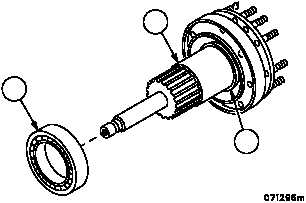

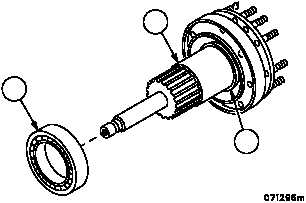

18. Heat roller bearing (2) to approximately 300 degrees F. Install roller bearing (2) on output shaft assembly (1).

Allow roller bearing (2) to cool to room temperature.

19. Support output shaft assembly (1) on inner race of roller bearing (2) in hydraulic press. Apply 10 tons of force

against flange to seat roller bearing (2) against spacer (5).

1

2

5

NOTE

FOLLOW--ON MAINTENANCE:

Install output reduction gear output shaft and

related parts (WP 0045 00).

END OF TASK